Frequently Asked Questions

1- What type of flooring is Sonoma Wood Floors?

Sonoma Wood Floors is an Engineered Hardwood floor. Engineered hardwood is more dimensionally stable than Solid hardwood. Engineered wood has a wider range of tolerance to fluctuations in temperature and humidity. (Installers must review NWFA guidelines on the range of suitable moisture and humidity levels for engineered wood).

2- What is Sonoma Wood Floors- Coastal collection?

Sonoma Wood Floors' Coastal collection is a curated group of 9.5" wide planks, hand selected artisan developed colors.

3- Why do real wood floors generally come in random length planks?

Usage of random length planks allow for less waste of wood making the process more environmentally friendly and economically productive.

4- Why should one prefer to purchase random length planks vs only full length planks?

It enables installers to create the staggered pattern installation that is usually associated with genuine wood floors while minimizing the need to cut full length planks.

Sonoma Wood Floors have a 4mm nominal wear layer. This is considered a healthy thickness for a wear layer. It can be sanded 2-4 times depending on the procedure employed to do so.

Since genuine wood floors, under normal use, generally do not need to be refinished for 20-25 years; Sonoma Wood Floors, with proper care and maintenance, will last for many decades.

5- Can Sonoma Wood Floor be sanded and refinished? If so, how many times will I be able to sand and refinish Sonoma Wood Floors?

6- What is UV Lacquer finish?

UV Lacquer finish is a finish applied on top of wood surface, cured and hardened by UV rays to leave a strong protective finish on wood. A UV Lacquer finish floor is considered low in maintenance while providing strong protection to the wood.

7-Why is UV Lacquer finish desirable?

In keeping with latest technologies in wood flooring finishes, Sonoma Wood Floors' UV Lacquer finish is designed to reduce visibility of wear and tear and make the flooring visually appealing.

Please note that the Sonoma Wood Floor colors are UV Lacquer finish except Bahia SMC120 and Bay Beach SWF240; which are UV Oil finish. Please see the notes below to learn about UV Oil finish (section 9) and its care and maintenance instructions (section 10). You may also refer to our Care and Maintenance page.

8- How to clean your UV Lacquer floor?

UV Lacquer floors are considered easy to care for.

For normal day to day cleaning, one may use dry or damp

(water wrung out) microfiber mop. A mop should never be dripping wet,

and no water should be left pooled or visible on or around your

wood floors.

One brand often used is the Bona cleaner for “hardwood floors”

(not the ones that is labeled “hard surface”). You want to use a cleaner

made specifically for Hardwood to protect your natural wood floor.

Please use cleaning products that do not contain harsh cleaning agents or surfactants as these cleaners can, over time cause damage to the factory applied finish.

Cleaners which claims to change the finish of your floors or add shine should NOT be used, as altering the finish will void your Sonoma Wood Floors' finish warranty. One such example is "mop and shine" products. Please do not use such products on Sonoma Wood Floors.

Please note that the Sonoma Wood Floor colors are UV Lacquer finish except Bahia SMC120 and Bay Beach SWF240 which are UV Oil finish. Please refer to the notes below to learn about UV Oil finish (section 9) and its care and maintenance (section 10). You may also refer to our Care and Maintenance page.

9- What is UV Oil finish?

UV cured Oil finish colors- Bahia SMC120 & Bay Beach SWF240.

A UV Oil finish is an oil finish which has been cured via UV (ultraviolet) light. As a result, the finish is stronger compared to a purely natural oil finish and requires easier maintenance than wax-oil finish. A UV oil finish usually has a low matte or satin finish.

Guidelines to maintain UV Oil finish floors are different than UV Lacquer finish. Please read below for additional information.

10- How to care for UV Oil floor, Bahia SMC120 & Bay Beach SWF240

Coastal Collection Bahia SMC120 & Bay Beach SWF240 are UV Oil finish. These are the only colors in Sonoma Wood Floors which are UV Oil finish.

Daily cleaning can be achieved by dry or damp (water wrung out) microfiber cloth.

For occasional intensive cleaning of UV Oil finish we recommend using Ciranova oil hardwood floor cleaning and maintenance products. You may also use Bona UV Oil finish cleaner.

11- Can I use vacuum cleaner to clean my hardwood floors?

You may use a vacuum cleaner to clean your hardwood floors. That being said, make sure to avoid the bristles or any rotating agitator bar from making contact with the floors as these could cause damage to the hardwood floors.

Also, you should be careful about any hard debris being stuck in the wheels or any portion of the vacuum moving over the floors as these could cause scratches on the floor.

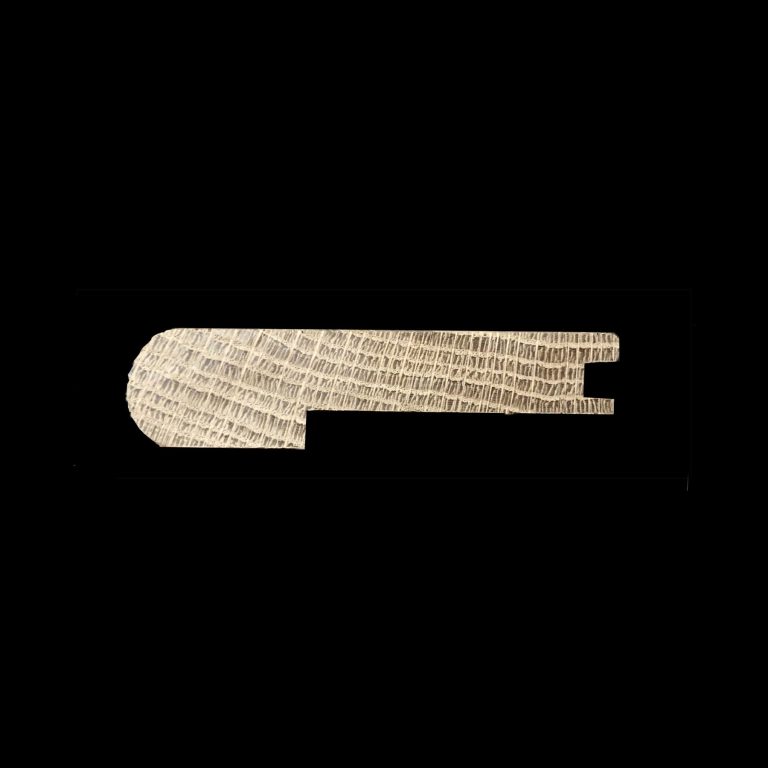

12- Micro bevel vs Straight or squared edge planks -

Sonoma wood floor planks are micro beveled.

Sonoma Wood Floors are micro beveled along all 4 plank edges. Micro-beveled floors maintain a distinction between individual planks, bringing an elegant design element to your space.

13- Is Sonoma Hardwood CARB compliant and low in VOCs ?

All Engineered wood products sold in California have to be CARB 2 compliant which regulates indoor air quality of your living space. Sonoma Hardwood is CARB2 TSCA title Vi compliant and Floorscore certified.

What Floorscore means – “FloorScore® is the most recognized indoor air quality (IAQ) certification standard for hard surface flooring materials, adhesives, and underlayments. Developed by SCS with the Resilient Floor Covering Institute (RFCI), a leading industry trade association of flooring manufacturers and suppliers, it qualifies for many green building specifications including LEED v4.1, WELL, BREEAM, CHPS, and Green Globes.”

14- Is Sonoma Wood Floors sustainably/ responsibly harvested?

Sonoma Wood Floors is Lacey act compliant.

Lacey act states, “the Lacey Act sets a groundbreaking precedent for the global trade in plants and plant products, acknowledging and supporting other countries’ efforts to govern their own natural resources and putting in place powerful incentives for companies trading in these commodities to do the same.”

15- Are moldings available for Sonoma Wood Floors?

Yes. We have co-ordinating moldings available for Sonoma Wood Floors. We offer flush Stairnose in round and square edge. Should you want the moldings to be 5.5" wide, those can be made available as well. Please contact your local representative to check further.

We also have co-ordinating End molding, Reducers, T-moldings and Quarter rounds.

Moldings are made to order. Please contact your representative to check the timeline on availability.

16- How do I install Sonoma Wood Floors ?

Sonoma Wood Floors are 9.5"wide plank engineered wood flooring. These should be installed with Glue down method.

Please refer to installation instructions for further installation related questions.

16- Do I need to acclimate Sonoma Wood Floors before installation?

As stated in Sonoma Installation guidelines, “Materials must be allowed to acclimate for as long as necessary to meet minimum installation requirements for moisture content. (a minimum of 72 hrs.). Do not open the boxes till the day of installation. Only open the boxes that are being installed that day.”

Please refer to installation instructions for further installation related questions.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.